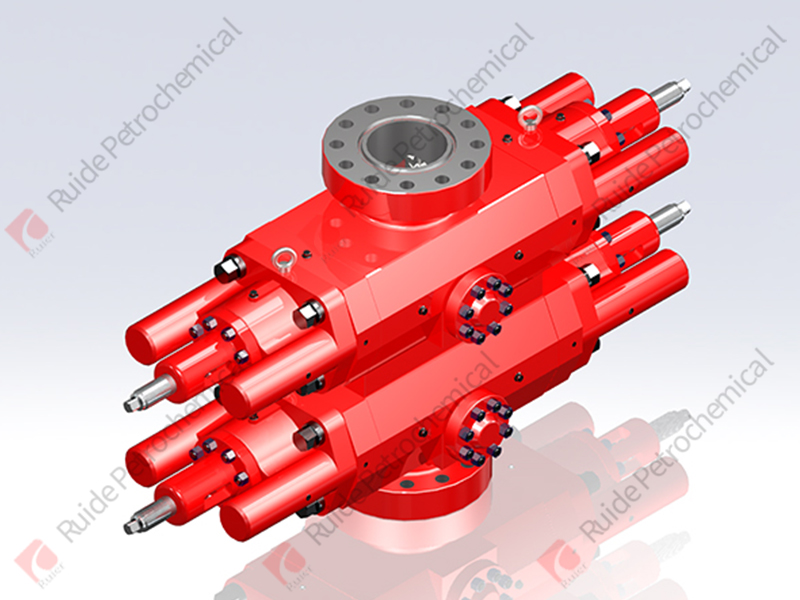

Double ram BOP

Ram BOP, shell and main parts are forged. The shell ram chamber is oval on the longitudinal section of the vertical piston rod. The ram is opened and closed by the piston rod pushed by the hydraulic cylinder. The side door moves in a straight line, and the action of the side door is controlled by two hydraulic cylinders. An automatic sand cleaning structure is designed on the shell. The ram is designed with automatic centering structure. Two outlets are designed on the side of the shell to connect the kill and choke manifold for mud circulation, choke and blowout, well killing, well flushing and other special operations. The cylinder body is designed with a discharge port, which can discharge the pressure and protect the device when the pressure is too high. The secondary sealing device is designed on the middle flange. In case of emergency, it is found that there is liquid leaking from the observation port, so emergency grease injection can be carried out.

Technical characteristics

The well shut in action is fast and can be realized within 3~8s.

It is easy to operate and can be controlled remotely.

The cavity adopts oblong section, with uniform stress and strong bearing capacity.

The side door assembly can realize hydraulic linear switch, which is convenient for ram replacement and on-site maintenance.

The side door seal adopts radial floating seal to replace the traditional end face seal.

The ram shaft seal adopts three seals, which are reliable.

The ram rubber core is self contained and has a large rubber reserve.

The function expansion is convenient, and the shear booster device, hydraulic locking device, etc. can be added.

Basic parameters

Nominal size: 7-1/16 "~21-1/4"

Working pressure: 2000PSI~20000PSI