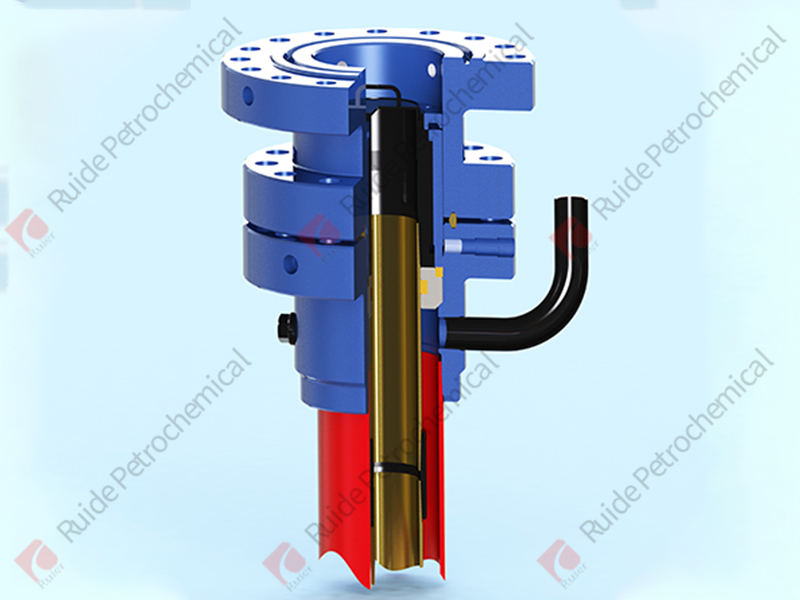

Thermal production casing head

Thermal production casing head is the main component of thermal production wellhead equipment in oil field. First, it is used to fix the wellhead of the drilling well, connect the downhole casing string, and bear the weight of the BOP; When high pressure and high temperature steam is injected into the well, the expansion range of the oil layer casing can be reduced; During the disassembly of wellhead equipment, it can effectively prevent the threads of the oil layer casing near the wellhead from loosening; When the mud steam flow is released, the annular space between casings can be effectively sealed, so that the mud steam flow is discharged from the control outlet pipe orifice.

Basic parameters

Relevant parameters of rated working pressure:

|

Rated working pressure MPa |

Applicable to thermal recovery conditions |

Applicable to drilling conditions at normal temperature (for reference only) |

||

|

Maximum working pressure MPa |

Maximum operating temperature ℃ |

Well bore depth (m) |

Wellbore pressure (MPa) |

|

|

30 |

21 |

370 |

<1400 |

<15 |

|

35 |

25 |

370 |

≥1400 |

≥15 |

Applicable minimum ambient temperature: - 29 ℃

Relevant parameters of drift diameter

|

Reservoir casing |

Vertical diameter of body flange (mm) |

Vertical diameter of seal pipe and stop pipe (mm) |

|

5½ ” |

254 |

122 |

|

7 ” |

254 |

157 |

Rated hanging load: 1200kN for 7 "casing (1000kN for 5 1/2" casing)